Supply chains play a critical role in economies all around the world. Every product and service has a supply chain. Effective supply chain management means the difference between having enough medicine, food or critical supplies to meet demand or facing shortages and bare shelves.

Supply chain management comprises forecasting and demand planning; sourcing and procurement of supplies and products; supplier management; manufacturing or production; inventory management; warehousing; the logistics of moving supplies and end-products among various facilities, warehouses, retail locations and the end customer; the reverse logistics of returned or damaged products; monitoring of industry trends to prepare for the future; and more. All of these moving parts must work together to deliver the products people need to work and live. Supply chain management professionals are the people who make this happen.

According to the ASCM Supply Chain Dictionary, supply chain management is the design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronizing supply with demand, and measuring performance globally.

Any product you can think of has a supply chain — take a package of cookies: At a high level, supply chain professionals at the company that produces the cookies would need to monitor sales and market data to forecast demand so they know how much to produce; source the ingredients; manage the process of baking the cookies; maintain the baking equipment; source packaging material; manage the packaging process; broker deals with retailers to sell the cookies; and move the cookies to warehouses and then to retailers, where the end-customer buys the cookies. In addition, they would also need professionals to help with risk management by maintaining product integrity throughout the manufacturing and shipping processes and recall items not fit for consumption, manage the people supporting operations, build relationships with suppliers and customers, measure progress, share appropriate data, innovate for new kinds of cookies, and more.

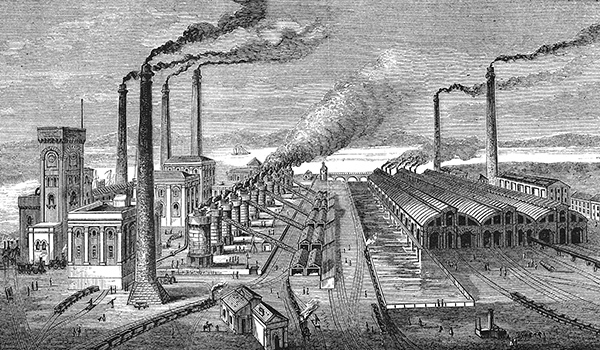

Some aspects of supply chain management have been around for centuries. Hyperlocal supply chains enabled communities to feed, clothe and house their members. Ancient trade routes required logistics and distribution to exchange goods around the world. Otherwise, supply chains were mostly localized until the mid-1700s, but they used many supply chain functions, including sourcing, manufacturing, logistics and distribution. The Industrial Revolution expanded manufacturing capabilities, and then railroad development in the 1800s expanded distribution capabilities. More transportation opportunities continued to increase the possibilities, as trucks, planes and drones were developed. When businesses could reach farther distances in less time, they expanded their markets, their manufacturing and sales plans, and ultimately their supply chains.

After capabilities came efficiencies. Mass production introduced more efficient manufacturing practices, pallets optimized warehousing and storage, and containers improved volume efficiency for logistics and distribution. More capabilities and efficiencies were unlocked with the availability of computers. Algorithms, spreadsheets and optimization models advanced planning, forecasting, production, inventory tracking, distribution monitoring and more. Supply chain management has continued to evolve at a rapid pace, constantly adapting to changing markets, advancing technology and a variety of disruptions.

At its core, supply chain management ensures companies are prepared to meet demand and that products and services arrive at the right place at the right time. The early 2020s demonstrated the importance of supply chain management and what can happen when companies are not prepared for changes and disruptions. During the pandemic, the supply-demand balance tipped severely, and consumers were left paying drastically increased prices or having to go without important items.

When supply chain links aren’t functioning properly, orders are not fulfilled, and people do not have the products they need. When effective supply chain management is applied, companies not only meet demand but have lower costs, higher efficiency, less risk, higher customer satisfaction, greater visibility of their operations and greater agility to respond to disruptions.

As supply chains extend their reach around the world, they can bring both necessary and new and exciting products to people in various countries. This can improve people’s lives in many ways — in particular, by more effectively meeting people’s needs and by creating rewarding jobs.

Supply chain management, like supply chains, includes many focus areas. The key components include:

The business function that attempts to predict sales and use of products so they can be purchased or manufactured in appropriate quantities in advance.

The process of combining statistical forecasting techniques and judgment to construct demand estimates for products or services across the supply chain from the suppliers’ raw materials to the consumer’s needs.

The process of identifying a company that provides a needed good or service.

The planning, scheduling and control of the activities that transform inputs into finished goods and services.

The branch of business management concerned with planning and controlling inventories.

The activities related to receiving, storing, and shipping materials to and from production or distribution locations.

The subset of supply chain management that controls the forward and reverse movement, handling, and storage of goods between origin and distribution points.

The activities associated with the movement of material, usually finished goods or service parts, from the manufacturer to the customer.

The identification, assessment and prioritization of risks followed by coordinated and economical application of resources to minimize, monitor and control the probability and impact of unfortunate events or to maximize the realization of opportunities.

Are you ready to learn more about the exciting and important world of supply chain management? Start by exploring these key topics:

To learn more about practical applications of supply chain management and what to expect in real-world scenarios, check out these resources:

ASCM also offers more content to help you learn from peers and experts

Simply subscribe today and you’ll receive valuable supply chain insights from the top leaders in the industry that will help you do your job better, faster, and more efficiently. From industry news to insider tips and trends, Signals delivers a quick read on the latest information on supply chain management right to your inbox.